Many modern products today require chemicals. It is often considered on elf the modern economy’s central industry, used in the production of over 70,000 products. Chemicals are usually used in the manufacturing process to transform the raw material into finished product. Manufacturing chemicals India supply to a range of industries, which can be industry broadly divided into:

- Basic chemicals

- Speciality chemicals

- Life sciences

- Consumer products

Of these, basic chemicals are the most widely found. Some chemical manufacturing companies also produce plastics. If you need chemicals in your manufacturing, it is important to understand the essentials of the process. Chemicals are often one of the most vital elements in manufacturing, effecting the overall grade, performance and the very look of the product. So, it is critical that you make the selection carefully.

Understanding what you need: A chemical is essential part of a carefully calculated and calibrated process. The exact quantity and quality is therefore, critical in the process. So, before you go shopping, make a precise calculation on what you need. You must also study every aspect of the element to be used. Be sure of issues like its chemical formulation, its properties and reactions. This could have a direct impact on its working, storage and disposal.

Knowing the grades of chemicals: Like many of our modern elements, chemicals have a good side and a bad side. If used without any checks, they cause serious harm to the living, including the earth. This is why chemicals are graded to indicate the levels of impurities they contain. There are three grades of chemicals — regent (ACS), laboratory (lab) and industrial (industrial). The classification is based on the impurities present and their suitability in different processes.

Regent chemicals are the purest, required to meet the most stringent standards. These are the chemicals that are fit for human or animal consumption. These are found in food and medicines. Laboratory chemicals have some traces of impurities. Other than items made for consumption, these chemicals can be safely used in manufacturing. Among the three, industrial chemicals contain the highest impurities. These are allowed only when the manufacturing process will not expose the users to the chemical. Knowing the grades is not just important for your manufacturing process, but also in the overall safety of the product. Using the right grade is critical when it comes to passing the required quality standards like ISO.

Research manufacturers: Since the quality of the chemical is a critical component in any chemical-based product, its manufacturing also becomes important. This means that you must be extremely careful on sourcing your product. Start with a thorough research on companies manufacturing chemicals in India. You can search for a company in online directories, trade forums or ask among your peers and acquaintances. Any company that comes personally recommended wins brownie points! You should then go through their websites thoroughly to check their manufacturing processes, products, certifications etc.

Gauging storage needs: There are certain conditions under which chemicals must be stored. The working of a chemical is often a function of environmental factors like temperature, humidity etc. This means that its storage can also have a detrimental impact on its composition. For instance, some chemicals have to stored at a temperature lower than the room temperature. In such cases, you must determine storage requirements, like temperature or humidity control spaces, special containers and so on. This will effect the budget and the space required, which will in turn, decide the amount of chemical you should buy at a time. So, determine the storage needs and capabilities before placing an order. Otherwise you may get stuck with chemicals and no way of storing them.

Responsible waste: Chemicals have to be disposed off in a responsible manner. Otherwise they can have a disastrous impact on the health of people handing the waste in particular and the environment in general. Every manufacturing process will produce such wastes. So, keep all your waste disposal machinery in place before buying your stock.

Supply: All details of the supply of chemicals must be determined and agreed upon well in advance. It can be useful to look for local companies to ensure a smooth supply. If you are choosing to source from a non-local source, be clear on the supply details — time taken, storage during transit, additional costs and so on.

The manufacturing chemicals India industry is one of the country’s most important sectors. With a number of small, medium and large corporations, it has emerged as a reliable and competitive market. However, one must be careful of all criteria before selecting a supplier.

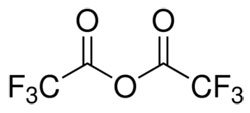

Amidst a large number of acids, trifluoroacetic acid is a popular name. This is normally abbreviated as TFA and is well-known as a strong acid. It is even more acidic than acetic acid. Its chemical compound is denoted as CF3CO2H. The electronegative trifluoromethyl group has a heavy influence on TFA. In a natural environment, it is available only in small quantity. It is obtained in sea water in small concentrations. Some of the alternative names of this acid are Perfluoroacetic acid, Trifluoroethanoic acid and Trifluoracetic acid.

Amidst a large number of acids, trifluoroacetic acid is a popular name. This is normally abbreviated as TFA and is well-known as a strong acid. It is even more acidic than acetic acid. Its chemical compound is denoted as CF3CO2H. The electronegative trifluoromethyl group has a heavy influence on TFA. In a natural environment, it is available only in small quantity. It is obtained in sea water in small concentrations. Some of the alternative names of this acid are Perfluoroacetic acid, Trifluoroethanoic acid and Trifluoracetic acid. The chemical industry is amongst the fastest developing sectors in India. The speciality chemical companies play a vital role in the economic development of the country. Sustained value creation and profitable growth forms the heart of a reputable speciality chemical company. Consumers’ penchant for value-added products which makes use of speciality chemicals of late has increased significantly. The rising environmental awareness has made the consumers conscious concerning the significance of eco-friendly goods.

The chemical industry is amongst the fastest developing sectors in India. The speciality chemical companies play a vital role in the economic development of the country. Sustained value creation and profitable growth forms the heart of a reputable speciality chemical company. Consumers’ penchant for value-added products which makes use of speciality chemicals of late has increased significantly. The rising environmental awareness has made the consumers conscious concerning the significance of eco-friendly goods.  The chemical industry is amongst the most competitive with new chemicals being introduced recurrently. However when it comes to choosing a leading chemical company one is often at a fix as this process is not an easy one. It is crucial for one in keeping into consideration few factors prior to selecting a company for satisfying all their chemical needs. Searching a reputable chemical company will be instrumental based on the success of one’s research. Below are few specific characteristics that one must consider when one is looking around for a leading chemical company.

The chemical industry is amongst the most competitive with new chemicals being introduced recurrently. However when it comes to choosing a leading chemical company one is often at a fix as this process is not an easy one. It is crucial for one in keeping into consideration few factors prior to selecting a company for satisfying all their chemical needs. Searching a reputable chemical company will be instrumental based on the success of one’s research. Below are few specific characteristics that one must consider when one is looking around for a leading chemical company.